With the widespread application of infusion therapy, infusion supplies have ranged from glass infusion bottles to polyvinyl chloride (PVC) soft bags to polypropylene and polyethylene (PP) hard plastic bottles. And fully comply with environmental protection non-PVC composite film soft bag. At first, due to the defects in packaging materials and infusion methods of glass bottle infusion, developed countries in the west began to develop flexible packaging for infusion in the 1950s. More than 95% of routine infusions used clinically in developed countries are packaged in fully enclosed soft bags.

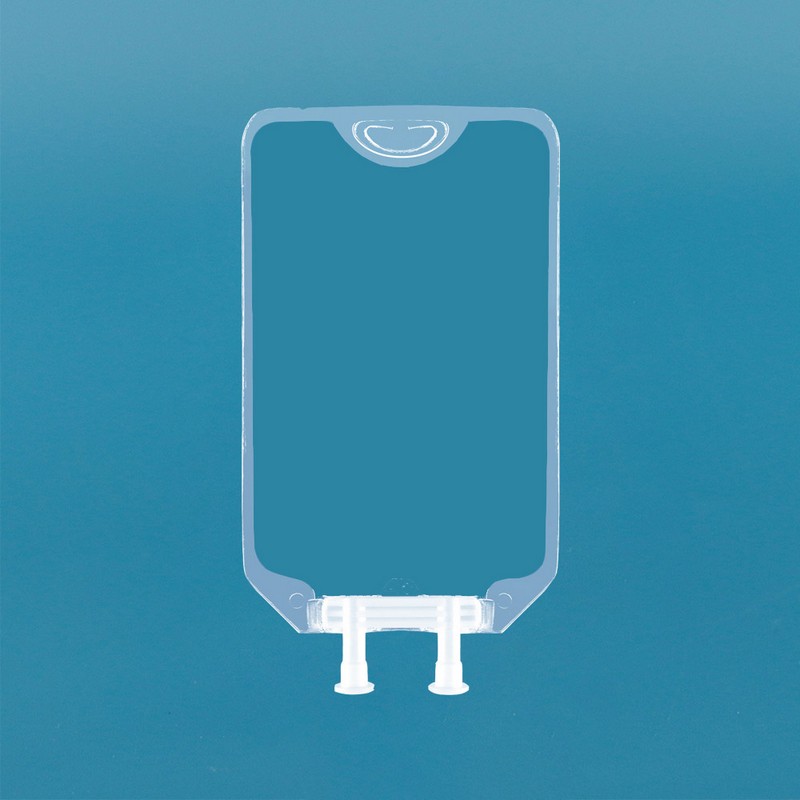

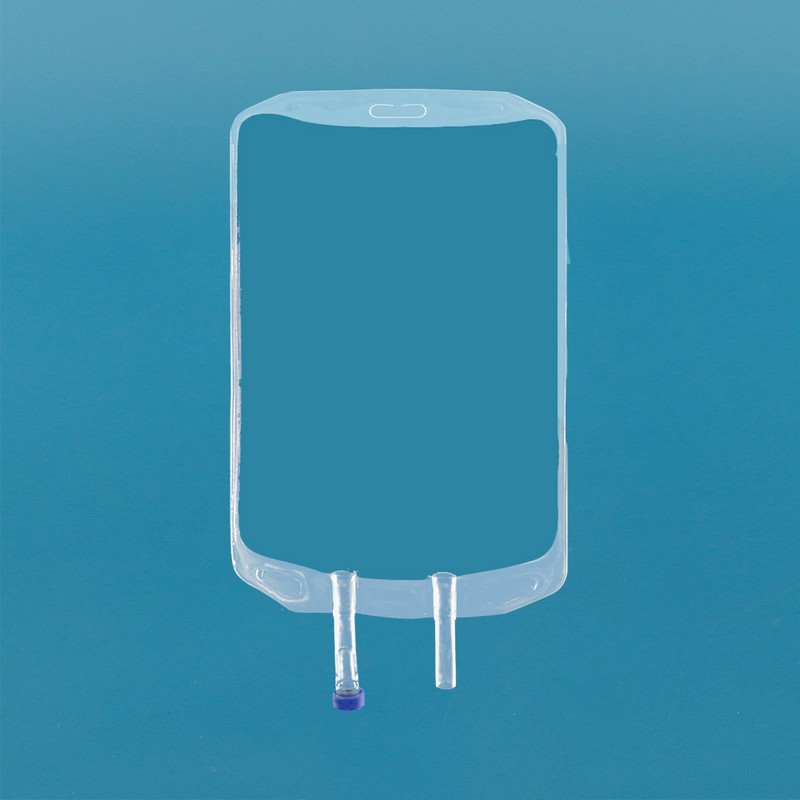

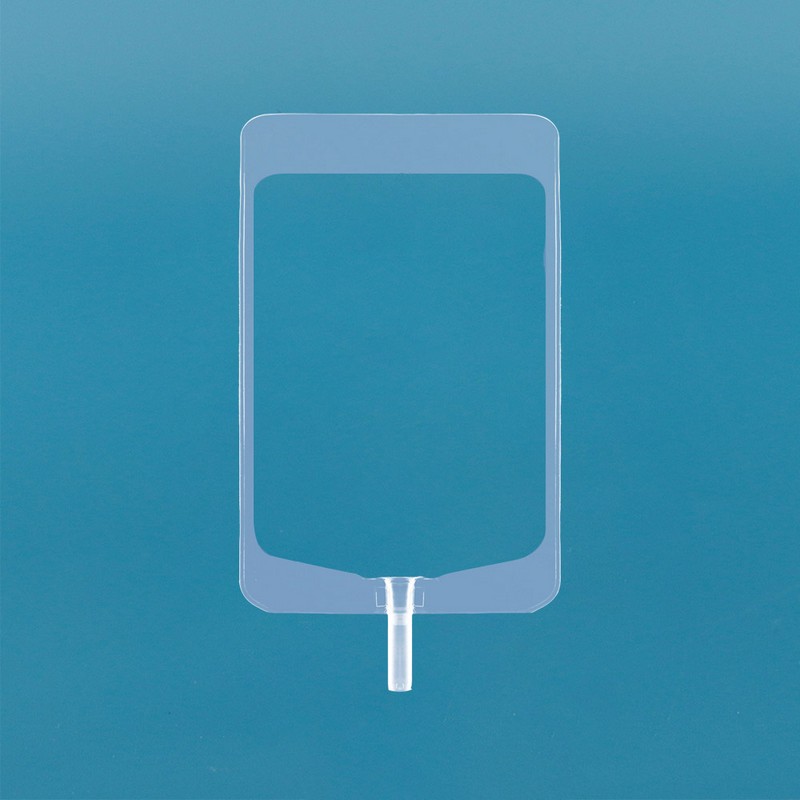

In recent years, the latest international packaging material—non-PVC multilayer co-extrusion composite film soft bag is increasingly widely used in infusion packaging abroad. The material quality of the composite film soft bag meets the standards of the European Pharmacopoeia, the Japanese Pharmacopoeia and the United States Pharmacopoeia, and has very low water permeability, air permeability and migration, suitable for the packaging of most drugs. The soft bag is made of non-PVC three-layer co-extrusion film without adhesive. The cleaning of the film and the forming of the soft bag are all completed in class 100 clean workshop, free of pyrogen and particles.