Product Features

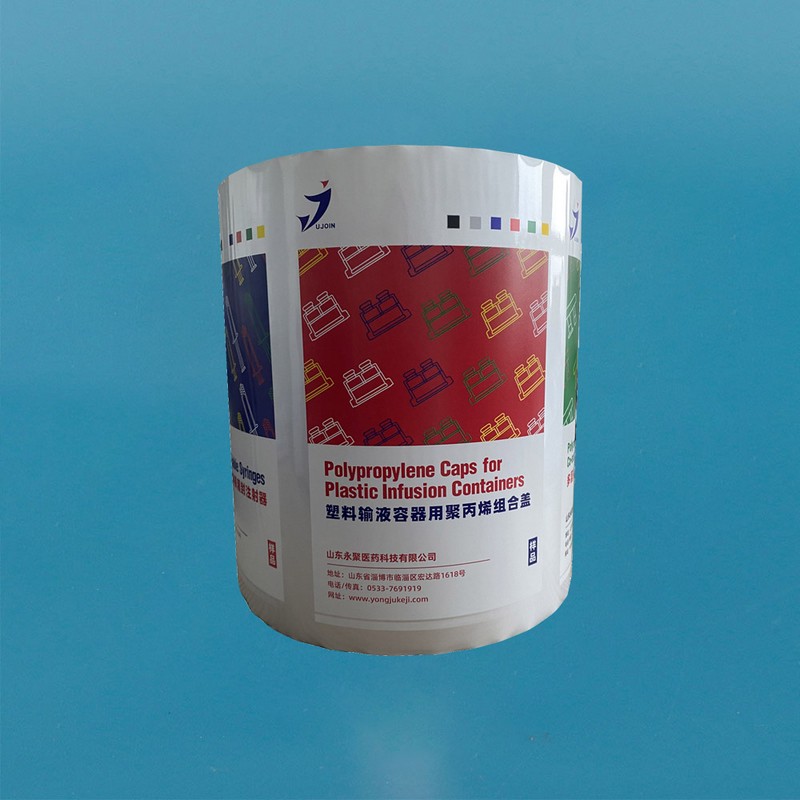

Aluminum-plastic Composite Film

1. PET layer: Good mechanical properties; resistance to grease and chemical solvents; good temperature resistance; low gas and water vapor permeability, excellent barrier performance; non-toxic, odorless, hygienic and safe.

2. AL layer: Greatly improve the water and oxygen barrier properties of film; safe and clean, effectively inhibiting the growth of bacteria or microorganisms; non-toxic and odorless, can be directly contacted with food; good light-proof performance, resistance to direct sunlight; strong temperature resistance, no precipitation.

3. PET layer (protective layer of AL layer): Prevent leakage of PE layer and avoid contact of contents with AL layer.

4.PE layer: ULDPE material, safe and clean, can be directly contacted with chemical liquid, and the leakage rate is extremely low; super heat-sealing performance and mechanical performance; stable chemical performance and good insulation.

Coated Composite Film

1. PET layer: Good mechanical properties; resistance to grease and chemical solvents; good temperature resistance; low gas and water vapor permeability, visible light transmittance ≥90%, excellent barrier performance; non-toxic, odorless, hygienic and safe.

2. Si coating: Greatly improve the water and oxygen barrier properties of film, and can still maintain relatively stable barrier performance in high temperature and high humidity environments; excellent ink affinity and good printing performance; safe and environmentally friendly, no harmful gases will be generated during combustion.

3. PA layer: High strength, high toughness, good puncture resistance; resistance to grease and chemical solvents; can be coated, metalized, or composite with other substrates to protect the coating from falling off; can be used at -60℃-150℃, wide applicable temperature range.

4. PE layer: ULDPE material, safe and clean, resistant to rubbing; super heat-sealing performance and mechanical properties; stable chemical properties, good insulation.

High-barrier Film

The new-type ultra-clean high-barrier pharmaceutical packaging film bag refers to a film with low permeability to low molecular weight chemical substances, such as gases and organic compounds. It can effectively maintain the original performance of the product and prolong the life of the product. It was initially used in food and pharmaceutical packaging. With the development and growth of China’s pharmaceutical industry, high-barrier plastic packaging materials have been rapidly developed and enriched in terms of quality, form, function, and variety, and have been widely used in the field of pharmaceutical packaging. At present, flexible and transparent pharmaceutical packaging high-barrier films are becoming a research hotspot in the international academic circle and a flashpoint pursued by the pharmaceutical industry.

Product Specifications

Coated Composite Film/Al-Plastic Composite Film/BOPP Film/PE Bag

Length is customizable. Width accepts customization. The material of each layer accepts customization. The number of layers of the composite film accepts customization

Application

Food Packaging, Pharmaceutical Packaging, High Barrier Bag.

Can meet the packaging needs of special drugs such as amino acids and fat emulsions.